Metalworking is a crucial industrial process that involves the creation, manipulation, and assembly of metal parts and equipment. This process relies heavily on machinery and machine tools that can shape and cut metals to precise specifications. One example of such machinery is the pipe and tube cut-off machine, a device used for cutting and shaping metal tubes and pipes.

Pipe and tube cut-off machines come in different designs and sizes, depending on their intended use and the materials they are meant to cut. They are capable of slicing through metals such as steel, aluminum, and brass, creating smooth and clean cuts that are essential for manufacturing high-quality metal products. These machines are vital in industries such as automotive, construction, and aerospace, where metal parts are essential.

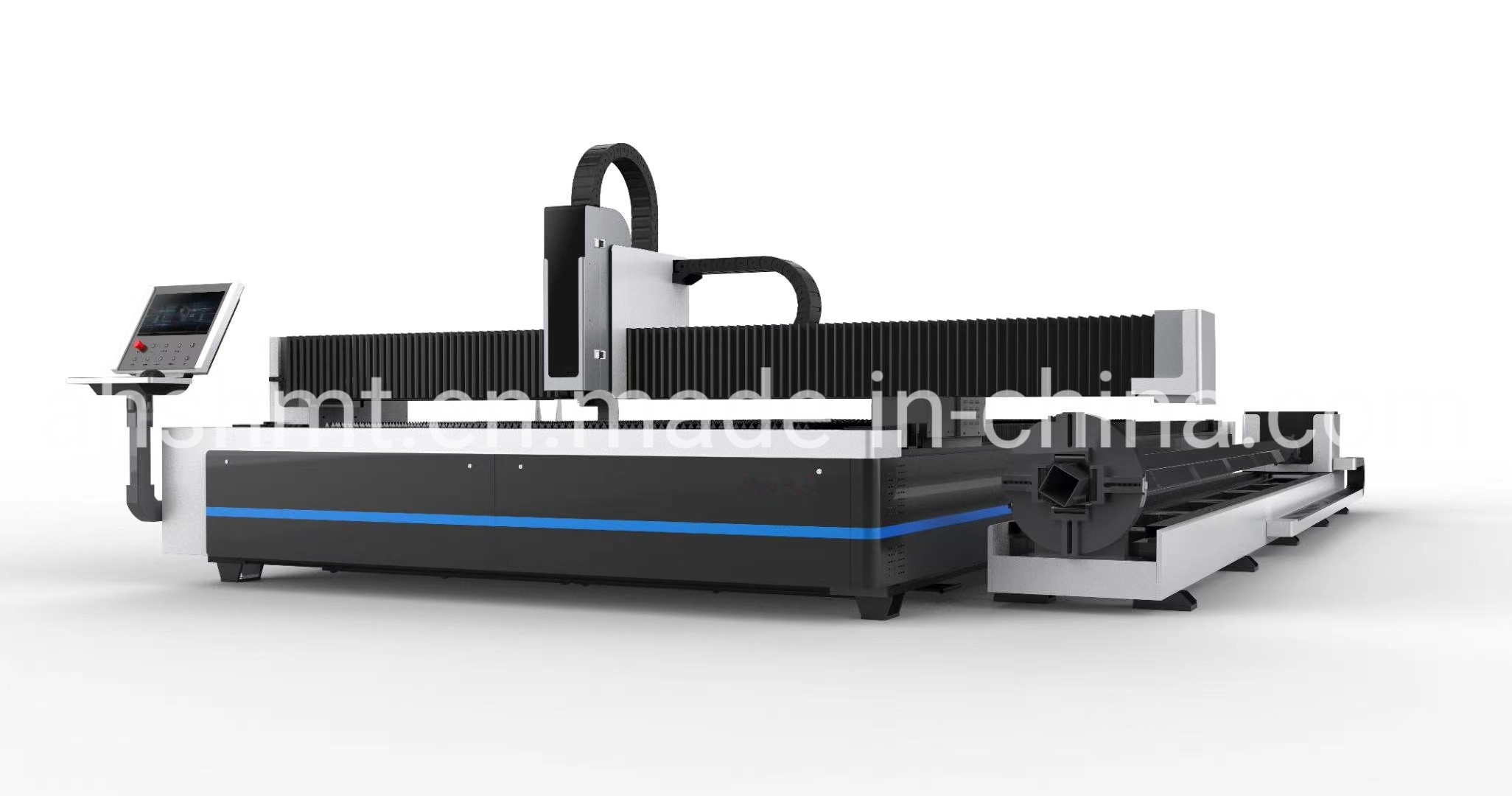

One type of pipe and tube cut-off machine is the lazer cut pipe and tube machine. This machine uses a laser beam to cut through metal tubes and pipes. Unlike traditional saws and blades, lasers offer a more precise cut that results in less waste and a cleaner finish. The use of lasers also reduces the risk of damage to the metal due to heat or deformation. Lazer cut pipe and tube machines are ideal for cutting complex shapes and designs in metal pipes and tubes, making them an essential tool in modern metalworking.

Another type of machine used in metalworking is the steel pipe and tube making machine. This device is used in the fabrication of metal tubes and pipes, and it relies on a series of rolls to shape and form the metal into the desired size and shape. Steel tube making machines come in different sizes and designs, depending on the diameter of the tubes being produced and the thickness of the metal. They are capable of producing tubes of different shapes, including round, square, and rectangular shapes.

Metalworking machinery, including pipe and tube making machines and cut-off machines, play a vital role in the manufacturing industry. They are responsible for creating the metal parts and equipment essential for industries such as construction, automotive, and aerospace. The machinery and machine tools used in metalworking are designed to create precise cuts and shapes, ensuring that the final products meet the desired specifications.

In conclusion, the metalworking industry relies heavily on machinery and machine tools such as the pipe and tube cut-off machine, lazer cut pipe and tube machines, and steel tube making machines. These devices are essential in shaping and cutting metal tubes and pipes to precise designs and specifications. They are the backbone of the manufacturing industry and are responsible for creating the metal parts and equipment necessary for many industries. As technology advances, these machines become more advanced and sophisticated, ensuring that metalworking remains an efficient and effective process.